Introduction:

Economic viability of any mineral deposit is estimated by sampling the mineralised body. Initially, the rock chips from the mineralised outcrops exposed on the surface is sampled and later stage channel samples from mine faces are collected, but for exploration geologist the most important samples are from drilled boreholes.

In mineral exploration programme, drilling in the initial stage is either for data collection or to test anomalies established by radiometric and non-radiometric survey methods (geophysical and geochemical) and to get information on stratigraphy like lithological succession, basinal structure or depositional or deformation history. Keeping the objective of drilling in mind the boreholes were carefully planned.

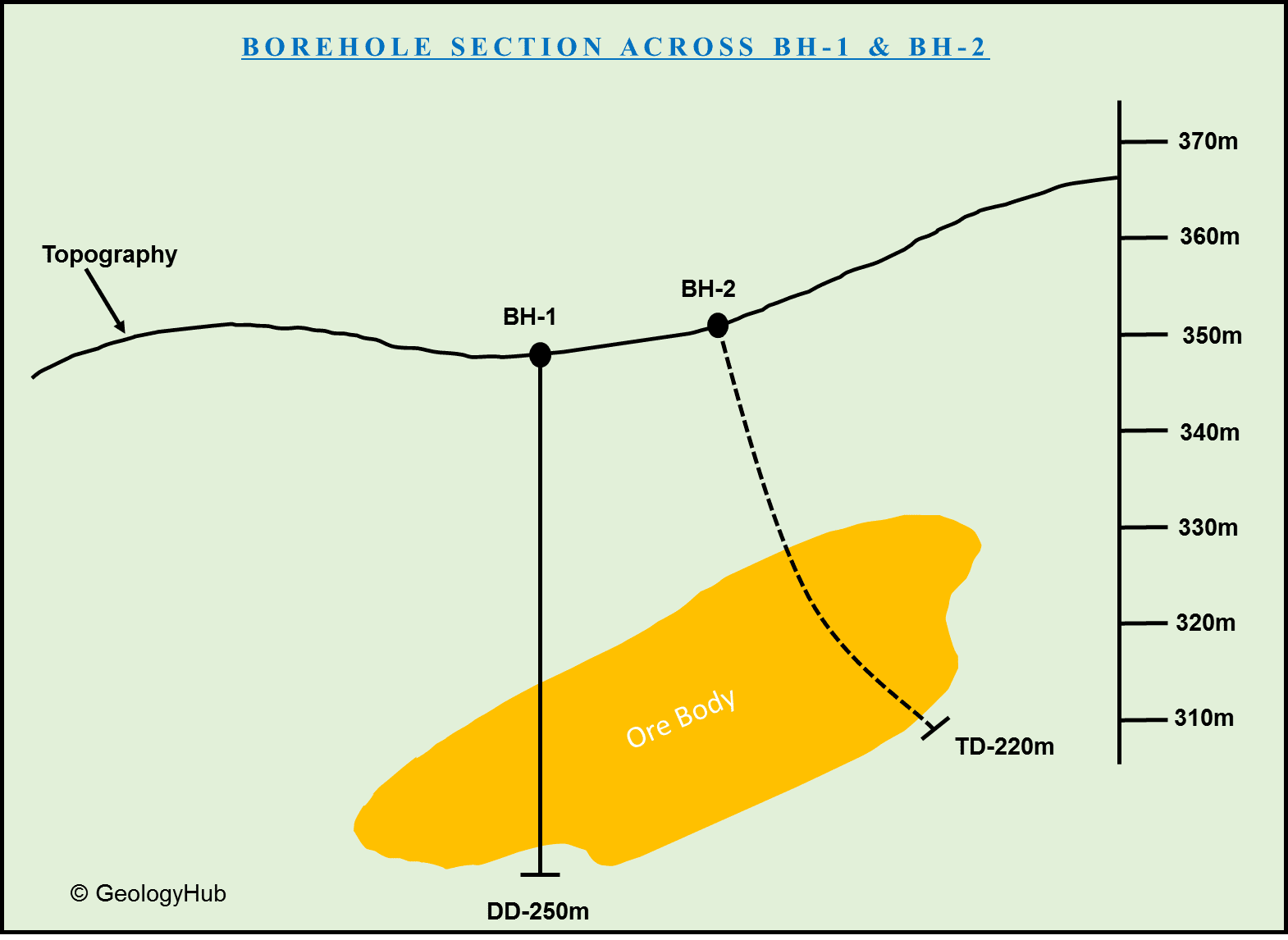

As an example, where the dip of a mineralised outcrop is not clearly visible usually two inclined boreholes are drilled from either side. But still, there are problems of exploration of ore bodies having a steep inclination or variable inclination on either side. In such cases sometimes same platform is used to drill a number of boreholes with different inclination after taking into account the possibility of deviation of the boreholes. Sometimes the surface features or topography is an important limitation for borehole planning. For example, the deep nalas or escarpments restrict the movement of drill rigs and in such cases, the planning of borehole needs special skills.

The initial or reconnoitory phase of drilling basically meant on testing the anomalies, identifying favourable target zones and the subsurface behavior of mineralisation on a broad sense for detailed evaluation. Once the mineralisation or nature of mineralisation is established, considerable meterage is drilled at the next stage during evaluation of deposit. Subsequently, different criteria are followed depending on the phases of exploration.

The prime objective in drilling is to determine the quantity and quality of minerals. The quantity means the volume of ore, thus, the aim of exploration is to ascertain the nature and configuration of ore body or size or shape of the deposit which has to be established in all three direction by drilling. Hence, the location of boreholes needs careful planning depending on whether the ore body has a surface manifestation or it is a blind ore deposit.

The geometry of ore body is very important as it is related to control of mineralisation and influences the decision about the spacing and inclination of boreholes. Geometrically, all mineral deposits fall into three morphological types -

a. Bodies with one short and two long axis examples horizontal low dipping and steep dipping beds, veins, sheets, lenses, etc. This type is widespread in nature like coal beds etc.

b. Bodies with one long and two short axis e.g. pipe like body, like kimberlite pipes.

c. Bodies which are more or less isometric e.g. stock works and masses.

Quality is generally determined by chemical and mineralogical composition of the deposit. Quantity and quality of mineral deposit are interrelated since the shape of the ore body is determined based on the accepted cut off grade.

Principles of Exploration

Exploration of all mineral deposit is governed by same set of principles. These are:

1. Successive approximation (including the principle of geological forecasting and verification).

2. Completeness of investigations.

3. Uniform reliability.

4. Less outlay of time and means.

According to the principle of successive approximation or geological forecasting and verification, every opening (borehole or sample point) either confirm the forecast or corrects it or rejects it for revision. Thus, geological model conceived through different stages of exploration needs verification and if required modification and re-verification. This process is continuous.

The principle of completeness of investigation is based on the fulfilment of objective at different stages of exploration i.e. determination of grade and quantity of mineral. Besides fulfilling these primary objectives, it should provide information needed for mine planning and mineral treatment technology with successive stages of exploration. The main problem which require earliest attention is the determination whether the deposit is monomineralic or poly metallic, establishment of its full outline and dimension across the strike for which reliable cross section of the ore body and host rock are required. Exploitation by mining in future requires detailed investigation not only of ore body but also of the host rocks which will be involved in the operation to some degree.

The principle of Uniform reliability is based on the variability of the deposit. It is well known that character like width, grade etc. are variable do not behave in similar manner in all directions and therefore borehole openings (sample points) are to be planned at larger spacing in the less variable direction and at shorter spacing in the more variable direction.

The principle of least outlay of time and means is a basic proposition for all industries. Means is divided between labour costs and materials. The time factor is most important for national economy as a whole, and it is sometimes expedient to accept greater outlay on labour and materials in order to save time on exploration of deposit.

Exploration stages

Exploration of a deposit is divided into three stages.

1. Preliminary stage

2. Detailed stage

3. Mine or exploitation stage

Preliminary stage: The objective of Preliminary stage exploration is to establish the general size, approximate shape and quality of ore body. At this stage detailed topographic survey is completed and accurate geological map (1: 5000 to 1: 10000 scale) is prepared. Exploratory openings are planned according to a definite system. The data obtained at this stage helps in selecting areas for subsequent detailed exploration in case of a very large deposit. Smaller deposits are usually completely explored at once in detail. Reserves estimated with the help of data obtained at this stage are classified as “Inferred Reserve”.

Detailed stage: The detailed exploration is undertaken only where a deposit is to be developed in near future. Objective of drilling in this stage is the estimation of total tonnage of ore and metal content, fixing the average tenor based on particular cut-off, the depth wise distribution/outlining the configuration of ore body for selecting mining methods, collection of samples for hydrometallurgical studies for mill parameters and detection of associated metals which could come out as by product etc. All these help the management to take an “investment decision”. Most vital in this stage is the confidence limits of such estimates. At this stage, the contour and attitude of each mineral body or ore lode is outlined with greater accuracy. The results are plotted on 1:500 to 1:1000 scale maps depending on the size and complexity of the deposit. To obtain reliable information at this stage, new exploration opening were driven, thus thickening the exploration grid, especially in those sections with more complex geology and those with richer concentration of mineral. Each new borehole is a separate sample point to reflect block grade from a relatively small volume of sample. The precision of estimation depends directly on the number of samples taken. In order to estimate the grade of a block with extreme precision it is necessary to sample intensively. Results of various sampling intensities can be analysed visa-a-viz the deviation from true mean. Intensive sampling can be prohibitively expensive even for the most valuable ores. So after examining the consequences of having “imperfect” knowledge of true block grades, one may be in a position to compromise i.e., to take only limited samples or drill minimum number of boreholes. Geostatistical analysis is applied at this stage.

Detailed exploration data provided a much more exact estimate of mineral reserve in the category of “Indicated Reserve”. The results obtained at this stage are utilized to draw up technical plan for exploiting the deposit. After this stage, a deposit may be handed over for development.

Mine or Exploitation stage: This stage begins as soon as mining operations start and continues until the deposit is almost worked out. At this stage, very accurate information is obtained in respect of grade and width of the deposit from the networks of levels, cross – cuts, raises, winzes etc. The outline of the mineral deposit is delineated most precisely. At this stage of exploration, an underground geological map is made from mine surveys on scales of 1: 100 to 1:500 scale, revealing detailed features of the deposit. Reserve estimated from the data obtained at this stage is classified as “Proved Reserve”.

CONCLUSION:

Planning of borehole is a continuous evolving process related to the stage of exploration for acquisition of data as per the allotted budget i.e., “cutting your coat according to cloth”. The exploration stages are sometimes clearly separated from each other, but they generally merge into a continuous process and the line between the preliminary and detailed exploration stage can not be easily drawn.

0 Comments:

Post a Comment